Products

Introduction of product

Standard conveyor chains / Sprockets

HOME > Products > Standard conveyor chains / Sprockets

Standard Conveyor Chains & Sprockets

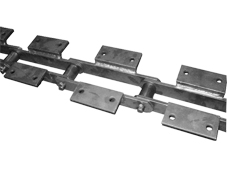

Standard Conveyor Chains Classification

Bando chains are used in various environments and industries and are custom-made to suit a wide range of equipment and working conditions. We can design and manufacture chains to match any specifications that our clients need. Standard conveyor chains classification is done by dividing by which types of rollers or attachments can be used.

Classification by Roller Type

Widely used in various industrial automation equipment.

Attachments can be made to match the condition of the using.

Attachment adjustments can be made to match the requirements of our clientele, regardless of their specifications.

Depending on the roller type, there are S,M,N,F,and R type rollers.

| Type | Photo | Description |

|---|---|---|

| S,M Type |  |

The roller diameter is less than the width of the link plate. Typically used in bucket elevators and flow conveyors for the purpose of protecting sprocket teeth and bushes. |

| R Type |  |

Diameter of the roller is larger than the plate width. Most commonly used type of conveyor chain. Usually used in small, medium-sized horizontal or inclined conveyors. |

| F Type |  |

Flanges are attached to rollers to guide rolling. Mainly used with a large-sized inclined or horizontal conveyor. |

| BUSHED type |  |

The role of the roller is replaced by a bush. Like trolley conveyors, chains are used only for tension transfer, while weight load is used for conveyors designed to carry with separate rollers. |

| Bearing type |  |

R-roller type and F-roller type bearing are included, and because the roller easily rotates inside, the load is higher than that of general rollers. |

Classification by Attachments

The format of the attachment can be selected based on the conditions of use In addition, as our base type models can be modified to suit particular specifications, please don’t hesitate to contact us with any inquiries. (+82-31-984-4435)

Widely used in all industries

Attachments can be designed to suit any working conditions

Adjustable attachment distance to meet user needs

Classified according to the type of roller and shape of the attachment (A, K ,SA ,SK ,G2, G4 etc.)

| Type | Photo | Description |

|---|---|---|

| A Type |  |

It is a type with blades on one side of the chain. The number of bolt holes are called A1, A2, A3. |

| K Type |  |

It is a type with blades on both sides of the chain. The number of bolt holes are called K1, K2, K3. |

| SA,SK Type |  |

It has vertical blades on one or both sides. |

| G Type |  |

It has bolt holes on one or both plates. The number of bolt holes are called G2 and G4. |

| Welded Type(ANGLE) |  |

It's a type with angle welding on the plate. |

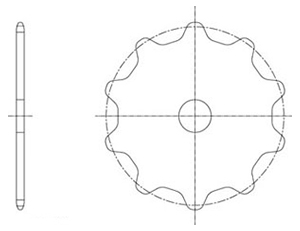

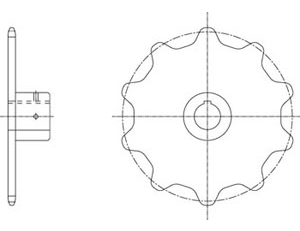

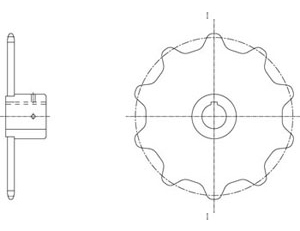

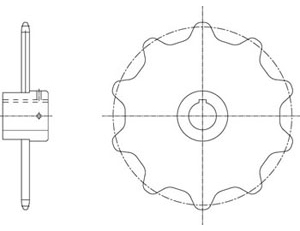

Standard Sprockets

The driving force of the motor is transferred to the main conveyor chain and sprockets. Because the format of the sprockets, teeth, material, number of teeth, and hardness selection has a direct relationship with the life of conveyor chain, it is imperative to select the most suitable parts.

Sprocket types are divided into BOSS (HUB), A type, B type, BW type, and CW types.

Please contact us for more specifications.

| BOSS(HUB)Type | Photo | Drawings |

|---|---|---|

| AType |  |

|

| BType |

|

|

| BWType |  |

|

| CWType |  |

|

Average Tensile-Strength

Unit (Kgf)

| Average Tensile Strength | |||||

|---|---|---|---|---|---|

| BANDO Chain | Carbon Steel | Carbon Steel (H.T) | Alloy Steel | Stainless 400 (H.T) | Stainless 300 |

| BD03000 | 3,000 | 4,600 | 7,100 | 5,500 | 3,400 |

| BD05000 | 7,000 | 11,000 | 14,500 | 11,000 | 7,000 |

| BD204 | 8,000 | 11,000 | 14,500 | 12,500 | 7,000 |

| BD450 | 8,000 | 11,000 | 14,500 | 12,500 | 7,000 |

| BD08000 | 8,000 | 11,000 | 14,500 | 12,500 | 7,000 |

| BD650 | 8,000 | 11,000 | 14,500 | 14,500 | 7,000 |

| BD10000 | 11,500 | 17,500 | 23,000 | 19,000 | 11,000 |

| BD214 | 13,000 | 20,000 | 24,500 | 19,000 | 12,500 |

| BD205 | 13,000 | 20,000 | 24,500 | 19,000 | 12,500 |

| BD6205 | 19,000 | 23,500 | 28,500 | 25,000 | 13,500 |

| BD12000 | 19,000 | 23,500 | 28,500 | 25,000 | 13,500 |

| BD17000 | 25,000 | 32,000 | 39,500 | 36,500 | 19,000 |

| BD212 | 25,000 | 32,000 | 39,500 | 36,500 | 19,000 |

| BD26000 | 32,000 | 46,000 | 53,000 | 47,000 | 25,500 |

| BD36000 | 48,500 | 60,000 | 69,500 | ||

| BD52000 | 54,000 | 83,000 | 105,000 | ||

| BD60000 | 62,000 | 95,000 | 106,000 | ||

| BD90000 | 95,000 | 140,000 | 166,000 | ||

| BD120000 | 113,000 | 169,000 | 225,000 | ||

KOR

KOR JAP

JAP