Technical Guide

Technical guide

Inspection / Maintenance

HOME > Technical Guide > Inspection / Maintenance

Inspection / Maintenance

Lifespan of Chains and Sprockets

If you use the chain for a long time, each part will be worn out and usage limits will be set according to the degree of wear.Abrasion of each part that affects its lifespan includes wear of the link plates, wear of the pins and bushes, wear of the rollers, pitch elongation and wear of the sprockets.

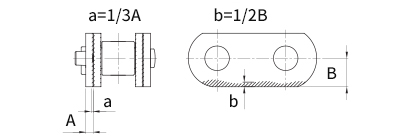

| 1) Link Plate Wear | |

|---|---|

|

The link plates are worn out from the bottom of the chains to the casing by the object being transported, wear between the link plates, and wear due to contact between the inside of the link and the side of the roller |

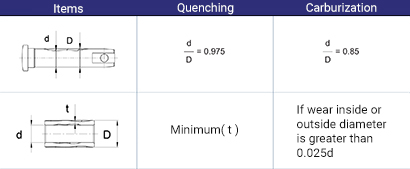

| 2) Inner-Wear of Pins and Bush | |

|---|---|

|

The bending phenomenon occurs when the chain and the sprockets engage, and if used for a long time, the pitch increases due to wear on the inner diameter of the pin and bush and it brings a result the elongation of the whole chain length. |

| 3) Wear of the Rollers | |

|---|---|

|

When compared to other parts, the wear of the outer diameter does not affect the performance. When using the R of F roller, depending on the wear of the contact side and/or bush contact point, rollers can be used until the bottom of the link plate comes into contact with the rail. If the plate begins to hit the rail, it not only increases the wear of the pins and bushes but also increases the frictional resistance. It can cause increased tension in the chain, insufficient output in the drive, etc. The usage limit of the S - roller is until the roller is broken due to a hole in the roller in an accurate assembly with the sprocket. |

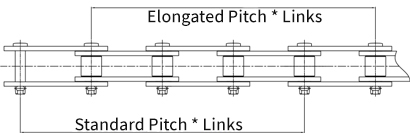

| 4) Pitch Elongation | |

|---|---|

|

As the chain engages the sprocket, or moves in the curved rail, the chain pitch is increased due to wear caused by the pin-bush connection. Chain elongation limits about 1 to 2% from the original chain pitch. As shown in the diagram, the amount of chain elongation is calculated by measuring the state of applied tension of more than 4 chain links or even links. |

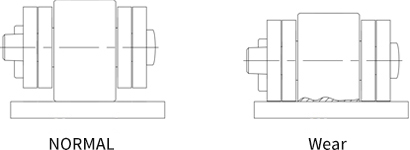

| 5) Sprocket Wear | |

|---|---|

|

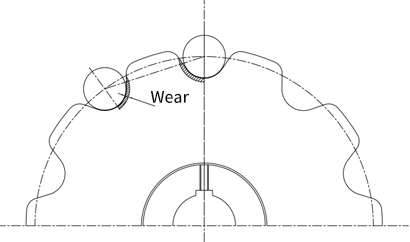

As shown in the picture, the wear of the sprocket's teeth can cause the chain vibrating due to the poor engagement. If the above phenomenon occurs, the wear can be corrected by grinding and welding for reinforcement. or reverse assembly of sprocket is possible. The wear on the bottom of the sprocket is proportional to the speed of the chain, and the usage limit varies slightly. Note: Select products with hardness between HV350 and HV600 from DF2B-B standards for build-up welding rods according to their wear conditions. Also, if the base welding is required due to high wear, use a D4316 welding rod. |

Adjust Chain Tension

The conveyor chain can't operate properly whether it's too tight or too loose. Especially if the sagging phenomenon is severe, check and adjust it in a timely as the chain may run over the sprocket teeth or interfere with the rails.

| Check up (When running 8 hours a day) | ||

|---|---|---|

| Within a week of commencing operation | Once a day | This chart for general use and should be checked more frequently when using it in poor conditions such as continuous operation, repeated loading, high temperature, corrosive environment, etc. |

| Within one 1 month of commencing operation | Once a week | |

| After 1 month | Twice a month | |

| Chain Tension Adjustment | |

|---|---|

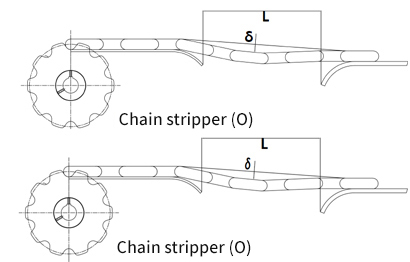

|

Check whether the chain operate smoothly with the sprocket. Leave enough space on the frame or rail to avoid interference of the apron, chain, etc. Avoid surging. |

|

| Horizontal Flow Conveyor | δ = 1/10L ~ 1/20L |

|

When operation is repeatedly interrupted When chain speed is high (25m/min) When chain is large or heavy When transferring materials of extreme heat |

δ = 1/15L~ 1/25L |

Sprocket Installation

Mounting accuracy of sprockets will affect the chain’s lifespan

Even if accurate installation is completed properly, the mounting condition may change due to vibration during operation, ground subsidence, etc. This effect causes wear and chain damage on the sides of the sprocket

Contact our technical department for tips on how to keep the axes horizontal. (TEL.031-984-4435)

Lubrication

It is paramount importance to lubricate chains regularly to ensure maximum lifespan of chains. For example, when powder and granular materials are being carried, such as in apron conveyors, one side is in direct contact with the transported material. Please adopt the presence or absence of lubrication in accordance with the transporting conditions.

Refueling points: between pins and bushes, between bushes and rollers, between links

Lubricant Type: SAE30 (-10°C to 0°C), SAE40 (0°C to 40°C)

Refueling interval: Approximately once a week

Refueling method: Dripping or coating

KOR

KOR JAP

JAP